News

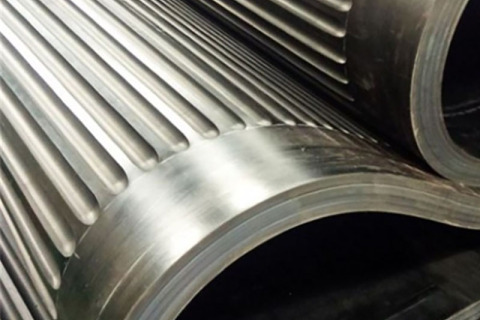

High abrasion resistant conveyor belt can meet the transportation requirements of heavy material transportation and mining industries. It is not only wear-resistant, but also ensures stable operation during use.

Multi ply belts are a kind of transportation tool used to transport various materials. Traditional conveyor belts cannot cope with high temperature environments. Our heat resistant conveyor belts are unique in design and material, and can adapt to high temperature working environments.

Traditional mining transportation methods have problems such as low efficiency, harsh working environment, and easy equipment damage during mining and resource transportation. Impact resistant conveyor belt can solve these problems. Conveyor belts for mining industry is a kind of transportation equipment designed for the mining industry. It uses conveyor belts to quickly transport materials such as ore, coal, sand and soil from the mining area to the processing, storage or transportation site. Coal mining conveyor belt not only improves work efficiency, but also improves the working environment of the mine and reduces the risk of operation.

In modern industrial production, conveyor belts play an important role. Whether it is mining, steel, chemical, port or energy industry, conveyor belts are used as a core means of transportation and undertake efficient material transportation services. Our company: Liaoning Hengyi has been committed to providing a full range of conveyor belt solutions for various industrial enterprises. Our goal is to enable customers' production lines to operate smoothly, while improving project efficiency and reducing operating costs and risks.

The joint is the top priority of the conveyor belt, and its strength is usually lower than that of the conveyor belt in the normal position. However, if the correct joint method and qualified products are used, we can significantly improve its strength. For example, the strength of mechanical joints can reach 40%-50%, cold-bonded joints are 60%-70%, and hot-bonded joints are as high as 80%-90%. It's like choosing the right glue to make the bond stronger.

As an indispensable core component of conveying equipment in modern industrial production, the selection of nylon conveyor belts not only directly affects production efficiency and product quality, but also concerns the company's operating costs and safe production. Scientific and reasonable conveyor belt selection can increase the service life of equipment by more than 30% and reduce energy consumption costs by 15%-20%. The following systematic selection guide will help you make the best decision.

The vacuum filter belt is an industrial filtration equipment used for solid-liquid separation, and is widely used in chemical, mining, food processing, environmental protection and other fields. Effective maintenance of the vacuum filter belt can greatly increase the service life of the vacuum filter belt.

In the cement production industry, the stability and durability of the conveyor belt are related to the operating efficiency of the entire production line. During the equipment upgrade process, a medium-sized cement enterprise in East China purchased a batch of nylon conveyor belts produced by our company. After three months of use, the person in charge of the enterprise's equipment department said: "This nylon conveyor belt not only has excellent tensile properties, but also runs smoothly, which solves our troubles of frequently replacing conveyor belts in the past." This case has attracted the attention of many buyers in the industry, and the advantages of nylon conveyor belts have been verified again. It is understood that the cement enterprise originally used ordinary cotton canvas conveyor belts, which need to be replaced every 4 months on average when conveying raw materials such as limestone and clay. Especially in the rainy season, wet materials cause the conveyor belt to absorb water and swell, which not only aggravates wear and tear, but also frequently slips. After multiple investigations, the company decided to try nylon conveyor belts. nylon conveyor belts use nylon canvas as a material, which has improved tensile strength and is suitable for long-distance, high-load conveying environments. The company's equipment engineer gave feedback: "After the new conveyor belt was put into use, it did not break even when running at full load, and it is very durable."

The corrugated conveyor belt is installed with corrugated skirts on both sides of the base belt to prevent the material from falling off the belt, thereby increasing the amount of conveyed material. The existing conveyor belt skirts are mostly made of rubber. During the material conveying process, if the overall bending performance is not good, it is easy to be torn, resulting in a relatively short overall service life. So how can we prolong the service life of the skirt of the corrugated conveyor belt?