Liaoning Hengyi Rubber Machine Belt Manufacturing Co., Ltd. was founded in 2018. It is a private enterprise that has grown from scratch in the turmoil of the market economy. After years of hard work, it has now developed into a professional production and transportation company at home and abroad. One of the major manufacturers of belt products.

The company is located in Xiaozhaimen Town, Liaozhong District,Shenyang City,Liaoning Province,China, covering an area of 20,000 square meters and a construction area of 18,000 square meters. The company currently has 150 employees, including 25 professional and technical personnel, including 4 with senior professional titles.

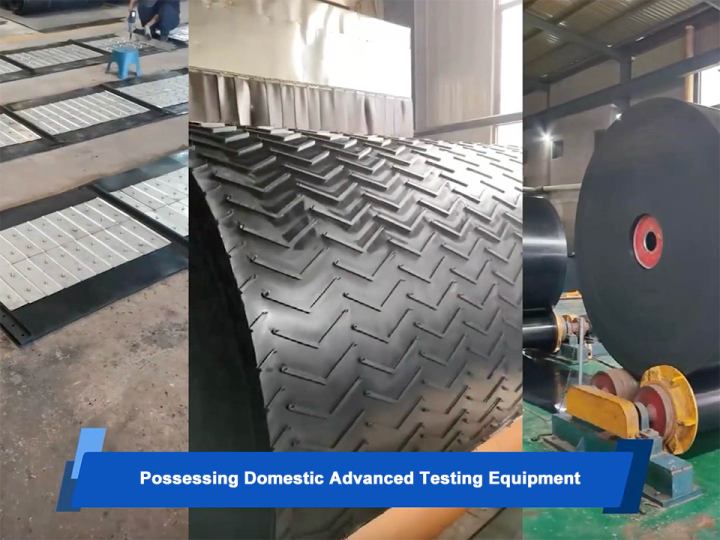

In 2021, it passed the IS09000 standard certification, IS09001 quality management system certification, IS014001 environmental management system and OHSAS18001 occupational safety and health management system standard certification, and obtained the AAA credit enterprise certification. The company has complete testing methods and has domestically excellent testing equipment, including a rotorless vulcanizer, Mooney viscometer, roller abrasion testing machine, 10-ton tensile testing machine, 2-ton tensile testing machine, aging box, high resistance meter, and roller friction Testing machines, etc.The company has advanced production equipment, including GK -270 internal mixer, 110 internal mixer, 1730 four-roller calendering unit, 1530 four-roller Calendering unit, 1.6-meter wide forming machine, 2-meter wide forming machine, and 10-meter steel wire core and fabric core conveyor belt vulcanization production line produced by Qingdao Beihai Machinery Equipment Company, 10-meter steel wire rope flat plate vulcanization production line produced by Liaoning Tieling, 8-meter double-layer Flat plate vulcanization production line, 10-meter single-layer flat plate vulcanization production line, molding six-layer laminating machine production line, molding four-layer laminating machine production line, with an annual output of 12 million square meters. The products are distributed in major provinces and cities across the country.

Factory Show

-

![Advanced Equipment]()

In order to ensure that product quality meets the standards, we continue to invest in advanced testing equipment and strictly implement testing procedures. From the acceptance of raw materials to the delivery of finished products, all products are verified by sophisticated testing equipment, and their various performance indicators meet international and industry requirements. Advanced testing equipment not only provides us with efficient and accurate testing methods, but also provides a solid guarantee for our quality control.

-

![Quality Control System]()

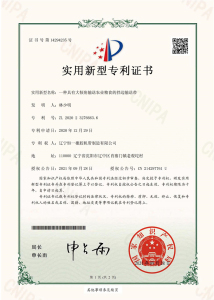

In our company, quality control is always the core link in the production process. As a manufacturer focusing on high-quality conveyor belts, we understand that the quality of each conveyor belt is related to the production efficiency and operational safety of our customers. Therefore, from the procurement of raw materials to the delivery of finished products, we have implemented strict quality control in each link to ensure that each product meets high standards.