- Home

- >

News

1. Flame retardant performance. The flame retardant conveyor belthas good fire resistance and flame retardant properties, which can prevent and control the occurrence of fire accidents. When a fire occurs on the conveyor belt, it can prevent the spread of the fire, delay the spread of the fire, and provide more time for personnel evacuation and fire fighting.

Coal mine energy is an important industrial pillar of many countries, but the underground transportation environment of coal mines is relatively harsh and the transportation conditions are poor, so it is very important to ensure the safety of conveyor belts. Since the 1980s, my country has begun to promote and apply flame retardant conveyor belts. The country has successively issued industry standards such as MT147.87, MT147-92, MT147-95, and MT914-2002, and implemented three certificates (inspection certificate, safety mark permit and production license) management for flame retardant conveyor belts to ensure the safety of underground conveyor belts in coal mines.

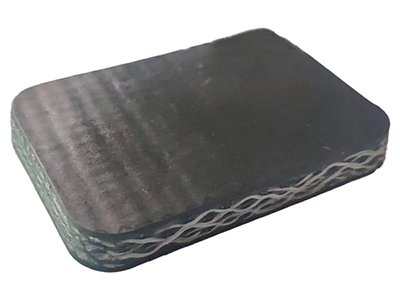

Heat resistant conveyor belt is mainly made of ethylene propylene rubber, which can withstand 600℃ high temperature for a short time or 200-300℃ high temperature for a long time. It is mainly composed of multiple layers of canvas covered with high temperature or heat resistant rubber, which are bonded together by high temperature vulcanization. It is generally used to transport hot coke, cement, slag, hot castings, etc.

The growing popularity of flame retardant conveyor belts highlights the growing focus on safety and efficiency across industries around the world. As businesses continue to operate in high-risk environments, the need for reliable, flame retardant materials has become even more critical. Flame retardant conveyor belts have become an integral part of modern industrial infrastructure in recent years, not only providing safety and reliability, but also supporting operational continuity.

As industry continues to prioritize safety and operational efficiency, demand for flame-retardant conveyor belts has surged. These specialized conveyor belts are increasingly being used in industries such as mining, chemical processing and manufacturing where fire hazards are prevalent.