Wear Resistant Fireproof Conveyor Belt

1. Fire resistant rubber textile conveyor belts have passed many rigorous tests, such as roller friction tests, and meet international standards.

2. Fire resistant rubber textile conveyor belts are specially designed for industries with high fire risks, such as coal mines, metallurgy, and thermal power plants, to improve equipment safety.

3. Fire resistant rubber textile conveyor belts not only have superior performance, but also have strong wear resistance and impact resistance.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

Introduction of abrasion resistant conveyor belt:

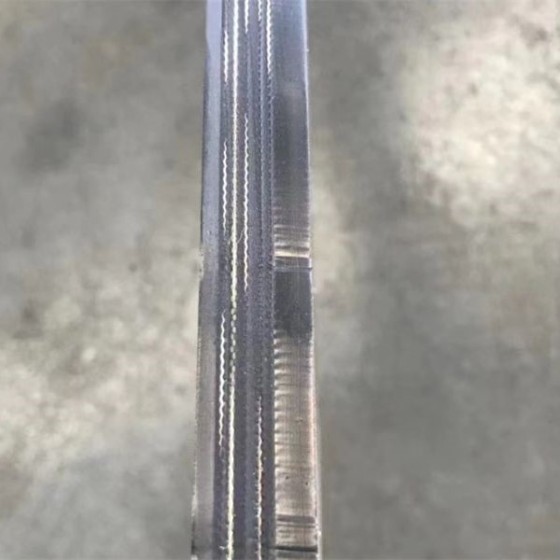

Abrasion resistant conveyor belt is a kind of conveyor belt designed for high temperature environment. The rubber material of abrasion resistant conveyor belt has unique reaction characteristics when it encounters high temperature, and can form a microporous carbonized layer. This carbonized layer not only has excellent burning resistance, but also effectively prevents heat from further transferring to the inside of the conveyor belt, thereby protecting the structural strength of the belt body and extending its service life.

Advantages of fireproof conveyor belt:

1. Fireproof conveyor belt can withstand direct contact burning of metal, minerals or other high-temperature materials.

2. During the operation of the conveyor belt, the carbonized layer of the fireproof conveyor belt will naturally produce irregular small cracks. These cracks help to dissipate heat on the belt surface, thereby achieving natural cooling.

3. Fireproof conveyor belt has tensile and wear resistance, achieving long-term stable operation.

FAQ:

1.How do we ensure quality?

There are always pre-production samples before mass production; There is always a final inspection before shipment;

2.What can you buy from us?

Nylon conveyor belts, wire rope conveyor belts, rollers, sweepers, etc.

About us:

We provide customers with a full range of high-quality services throughout the entire process of pre-sales, sales and after-sales. Before sales, our customer service team will provide professional product selection suggestions and recommend suitable products based on the customer's production process and transportation needs. During the sales process, we track the progress of orders through a real-time production management system, and use strict packaging and efficient logistics methods to ensure that the products are delivered safely on time. After sales, we provide comprehensive technical support, including installation and commissioning guidance and maintenance suggestions, to help customers successfully complete the project. We strive to make you feel at ease and satisfied in every link.