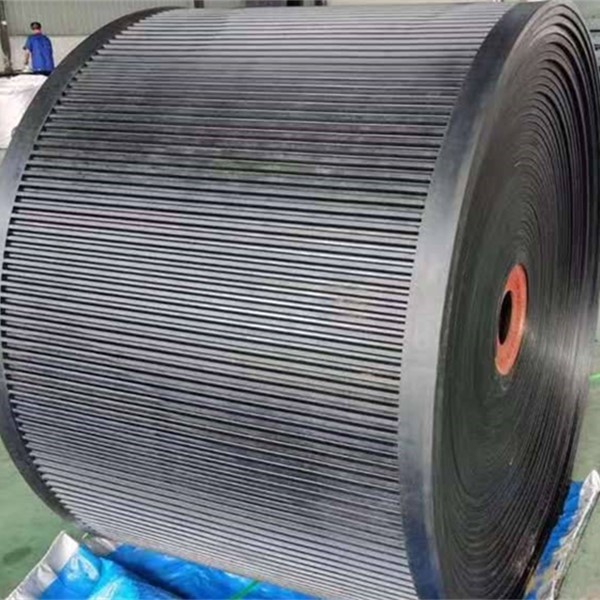

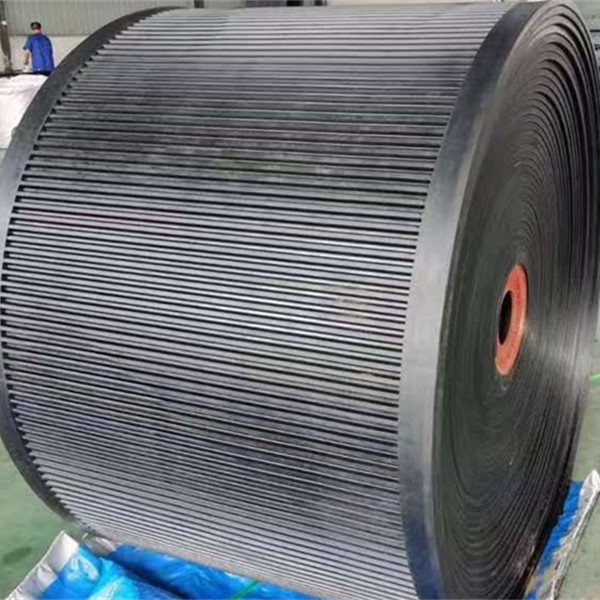

Vacuum Rubber Filter Conveyor Belt

1. Abrasion resistant conveyor belt combines gravity and vacuum technology, the filtrate is separated quickly, and the filter cake is dehydrated thoroughly.

2. The design of abrasion resistant conveyor belt is simple and easy to use, which reduces manual intervention and improves production efficiency.

3. Nylon rubber conveyor belt supports multi-industry applications and meets various needs from ore processing to food production.

- Hengyi

- Shenyang, China

- Depends on the actual situation

- 12 million ㎡ /year

- Information

Introduction of nylon rubber conveyor belt:

The nylon rubber conveyor belt forms a continuous circulation groove for accommodating and conveying filter cloth, filter cake, suspension and washing solvent. The nylon rubber conveyor belt achieves efficient separation of filtrate through gravity and vacuum at the same time. The filtrate passes through the horizontal grooves of the belt and the vacuum boxes arranged longitudinally, and is finally siphoned out from the drainage hole in the center of the belt. The dried filter cake is easily detached through the curved tube drum, completing the entire filtration process.

Advantages of rubber conveyor belt:

Our rubber conveyor belt is designed for solid-liquid separation and is an important part of vacuum belt filtration. With its unique structural design and excellent performance, rubber conveyor belt is widely used in mineral processing, chemical manufacturing, food processing, flue gas desulfurization system, fertilizer production and other fields to meet a variety of industrial needs. In addition, we can use skirts to increase the capacity of rubber conveyor belt and help prevent overflow. Skirt style and height are determined according to each specific application.

Application scenarios of abrasion resistant conveyor belt:

1.Mineral and ore processing: Solid-liquid separation and filtrate discharge.

2.Chemical and dye manufacturing: Filtration and separation in fine chemical production.

3.Food processing: Removal of solids in suspensions and liquids.

4.Coal and paper industry: Wastewater treatment and material filtration.

5.Flue gas desulfurization system: Efficient separation of desulfurization wastewater and filtrate.

6.Fertilizer production: Filter cake drying and waste liquid discharge.

About us:

Our factory is equipped with a variety of advanced testing equipment and strictly implements full-process quality inspection, from raw material acceptance to finished product delivery, so that each conveyor belt meets international and industry standards. In addition, real-time testing is carried out during the production process. By introducing efficient and precise testing technology, we can accurately grasp product performance, continuously optimize production and testing processes, and meet customers' high standards.