Mining Conveyor Belt Rollers

1. Conveyor nylon rollers transmit power through friction with the conveyor belt, which can ensure the stable operation of the conveyor belt under harsh working conditions such as heavy load and high speed.

2. The coating of conveyor nylon rollers is made of corrosion-resistant materials and can be used in chemical environments to extend the service life of the product.

3. Conveyor nylon rollers are made of environmentally friendly materials and do not pollute the environment.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- Depends on the actual situation

- Information

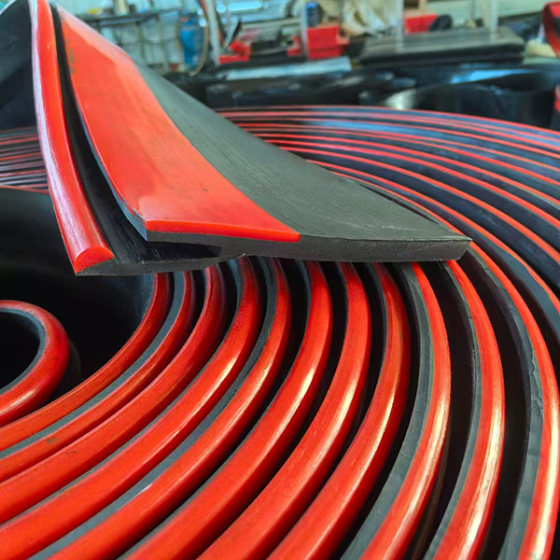

Introduction of rubber coated conveyor drive rollers:

Rubber coated conveyor drive rollers are the core components of the conveying system, mainly used to drive and support the conveyor belt to ensure the stable transportation of materials in the mining environment. Rubber coated conveyor drive rollers are usually made of high-strength steel. After special surface treatment, Rubber coated conveyor drive rollers have excellent wear resistance, corrosion resistance and high strength performance, and can operate efficiently under harsh working conditions.

Features of mining conveyor belt rollers:

Mining conveyor belt rollers have efficient driving performance, providing strong power transmission and ensuring smooth operation of the conveyor belt. The surface of mining conveyor belt rollers is treated with excellent wear resistance, which can not only extend the service life of mining conveyor belt rollers, but also minimize the wear of conveyor belts. Precision machining can ensure the roundness and coaxiality of the surface of mining conveyor belt rollers, thereby reducing system vibration and noise. In addition, the bearing design of mining conveyor belt rollers adopts high-quality bearings and sealing structures to prevent lubricant leakage and block dust ingress, ensuring optimal performance in harsh mining environments.

Industrial rubber roller model selection:

Industrial rubber rollers should be selected based on the power of the conveyor, the type of conveyor belt (such as strength, width, etc.), the working environment (such as humidity, temperature, dust, etc.), and the spatial layout. For example, when the power is not large and the ambient humidity is low, smooth industrial rubber rollers can be used; when the environment is humid, the power is high, and it is easy to slip, rubber-surfaced industrial rubber rollers should be used.

Maintenance of conveyor nylon rollers:

1. Check the wear of industrial rubber rollers regularly, and replace the severely worn rollers in time.

2. Remove the adhesion on the surface of industrial rubber rollers to prevent the accumulation of adhesion from affecting the transmission of industrial rubber rollers and causing damage to the belt.

3. Check the bearings and lubrication of the conveyor nylon rollers to ensure that the bearings are flexible and well lubricated.

4. Check the fixing device of the roller regularly to ensure that the conveyor nylon rollers are firm and reliable.

Our factory:

Our factory is a modern manufacturing enterprise integrating R&D, production, assembly and sales, focusing on the production of high-performance conveying equipment and its core components. With advanced technology, sophisticated equipment and strict quality control system, we are committed to providing customers with high-quality and reliable product solutions. The factory adheres to the concept of green manufacturing, focuses on sustainable development, and is customer-oriented, providing professional customization services and comprehensive after-sales support. Our products are widely used in mining, chemical, building materials and other industries, and are exported to domestic and overseas markets.