Metallurgical Conveyor Belt

1. Metallurgical industry conveyor belt adopts antistatic material, which effectively reduces the risk of fire and explosion and improves the safety of the working environment.

2. Metallurgical industry conveyor belt adopts modular design, which makes the installation process faster and can be put into use quickly.

3. Metallurgical industry conveyor belt is made of high temperature resistant material, which can withstand materials with temperature up to 200°C or even higher, ensuring that the conveyor belt is not damaged by overheating and prolonging its service life.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

Introduction of rubber conveyor belt:

Rubber conveyor belt is specially designed for metallurgical industry, mainly used for conveying high temperature, highly corrosive and heavy load materials, such as ore, coal and waste. Rubber conveyor belt is made of high temperature resistant, corrosion resistant and wear resistant materials, with excellent antistatic performance and excellent load capacity, and can withstand long-term operation in harsh environment. Rubber conveyor belt has flexible structure, can be customized according to different working conditions, is easy to install and maintain, and has the advantages of low energy consumption and long service life. It is an ideal conveying equipment with high efficiency, safety and environmental protection in metallurgical production.

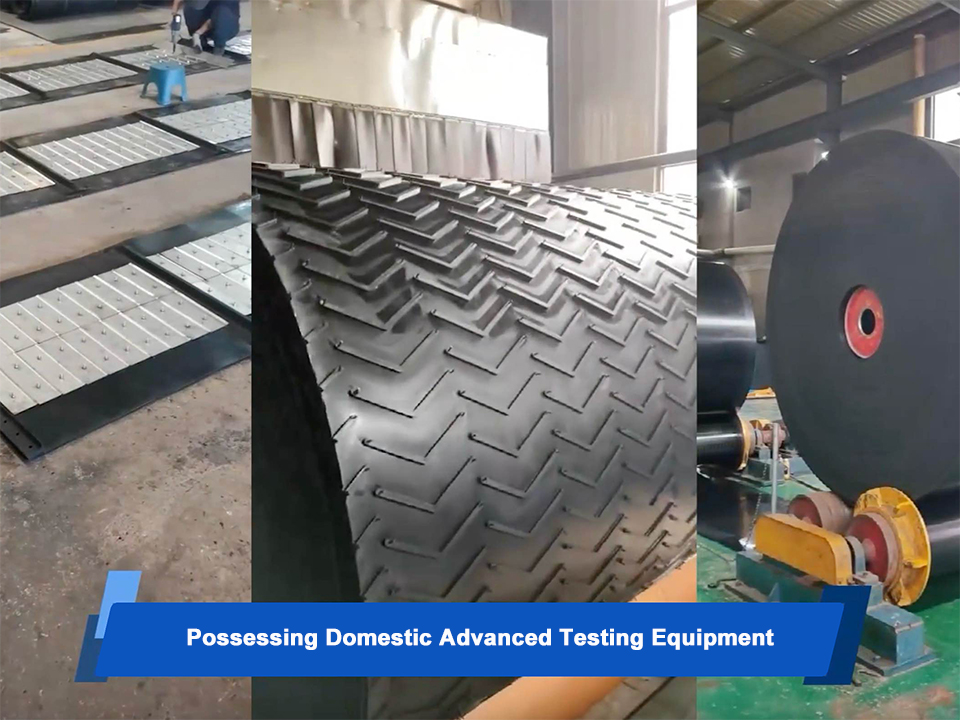

Features of bulk material conveyor belt:

Since bulk material conveyor belts often need to transport rough, sharp ores and metal waste, in terms of material selection, bulk material conveyor belts use highly wear-resistant materials and highly seismic-resistant structural design, which have good wear resistance, can effectively reduce wear and reduce maintenance costs. In terms of energy utilization, compared with traditional conveyor belts, bulk material conveyor belts can effectively reduce energy consumption and save electricity costs by reducing the friction between the conveyor belt and the fixing device, so that the kinetic energy will not be lost during the working process. In addition, the efficient conveying capacity can reduce the energy waste during transportation and meet the requirements of environmental protection. Considering that the temperature of the materials transported by bulk material conveyor belt is usually high, high temperature resistant materials are used in its production, which can withstand materials with temperatures up to 200°C or even higher, to ensure that the conveyor belt is not damaged by overheating and extend its service life.

Application of rubber conveyor belt:

1. Metallurgical industry:

Due to the large amount of ore, slag, coke and other materials involved in the metallurgical process, these materials are often large in size, heavy in weight and easy to slip. With the rubber conveyor belt high friction and anti-seismic performance of the conveyor belt, Rubber conveyor belt can be transported stably and efficiently.

2. Mining:

In the field of mining, metallurgical round pit conveyor belts also play an important role. During mining, a large amount of ore needs to be transported from the mine to the ground, and then processed through crushing, screening and other processes. The metallurgical round pit conveyor belt can adapt to the harsh environment of mining, such as high temperature, humidity, dust, etc., to ensure the stable transportation of ore and improve the efficiency and safety of mining.

3. Coal industry:

The coal industry is also one of the important application areas of metallurgical industry conveyor belt. During the mining, processing and transportation of coal, the metallurgical round pit conveyor belt can stably transport coal, prevent coal from slipping or accumulating during transportation, and ensure the continuous supply of coal.

Our sereves:

We attach great importance to the pre-sales and after-sales service experience of every customer, and are committed to providing comprehensive, caring and efficient service support. In the pre-sales stage, our professional team will provide detailed product consultation, customized solutions and comprehensive technical support according to your specific needs to ensure that you can choose the product that best suits your needs. In the after-sales stage, we promise to provide fast-response maintenance services, comprehensive user training and long-term warranty commitments. No matter what problems you encounter in the process of using bulk material conveyor belts, we will do our best to solve them for you. Our goal is to always be customer-oriented and establish a long-term and stable cooperative relationship.