Abrasion Resistant Nylon Conveyor Belt

1. The high abrasion resistant conveyor belt's wear-resistant coating and reinforced nylon fabric core provide long-lasting performance in even the most demanding environments.

2. High abrasion resistant conveyor belt adopts flexible design, customers can adjust it according to their own needs.

3. The materials used in high abrasion resistant conveyor belt meet environmental protection requirements and have no pollution to the environment.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

Introduction of abrasion resistant conveyor belt:

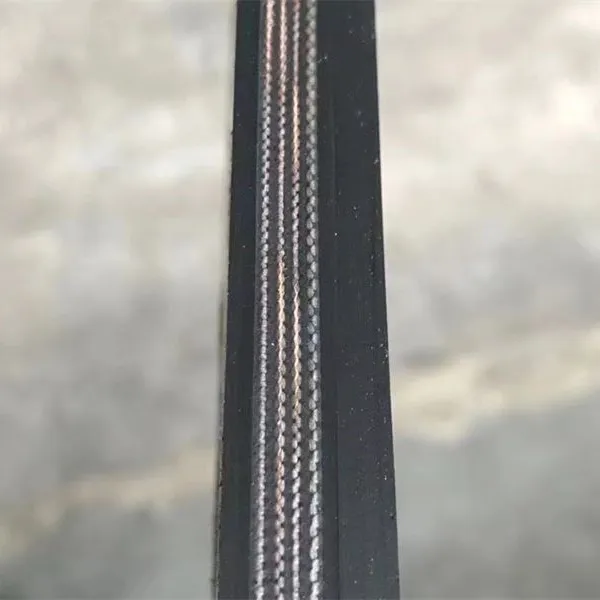

Abrasion resistant conveyor belts are designed to meet the rigorous demands of industries that handle abrasive materials every day. Abrasion resistant conveyor belts feature a rugged nylon core for excellent tensile strength, while the outer surface is treated with advanced wear-resistant compounds. This combination makes the conveyor belt not only durable but also flexible enough to operate efficiently under heavy loads and high speeds.

Features of Conveyor belts for coal mine:

Conveyor belts for coal mine use wear-resistant coatings and reinforced nylon fabric cores in material selection, which minimizes downtime and replacement costs and ensures stable operation. Conveyor belts for coal mine are able to resist the impact of environmental conditions such as temperature fluctuations, humidity and chemical exposure, ensuring reliable operation in different environments. Conveyor belts for coal mine provide enterprises with a cost-effective solution with durability and low maintenance requirements.

Application of conveyor belts for coal mine:

Conveyor belts for coal mines are widely used across industries requiring efficient material transportation. In mining, they handle ores, coal, and other abrasive materials, while in cement production, they transport raw materials like limestone and clinker. The construction industry relies on them for moving sand, gravel, and aggregates, and in steel and metallurgy, they are used to transfer metal raw materials and slag. Additionally, in agriculture, they facilitate the bulk handling of grains, seeds, and fertilizers, making them indispensable for high-volume operations in diverse industrial sectors.

Our Factory:

Our company has been deeply involved in this field for many years and has its own product processing plant, equipped with an experienced engineering and technical team and first-class testing equipment. Before the products leave the factory, they will undergo layers of screening by the factory department and quality inspection department to provide customers with rights protection.