How To Improve Efficiency With Nylon Conveyor Belt

2024-12-13 10:05Nylon conveyor belts improve efficiency in a variety of industrial environments through several key factors:

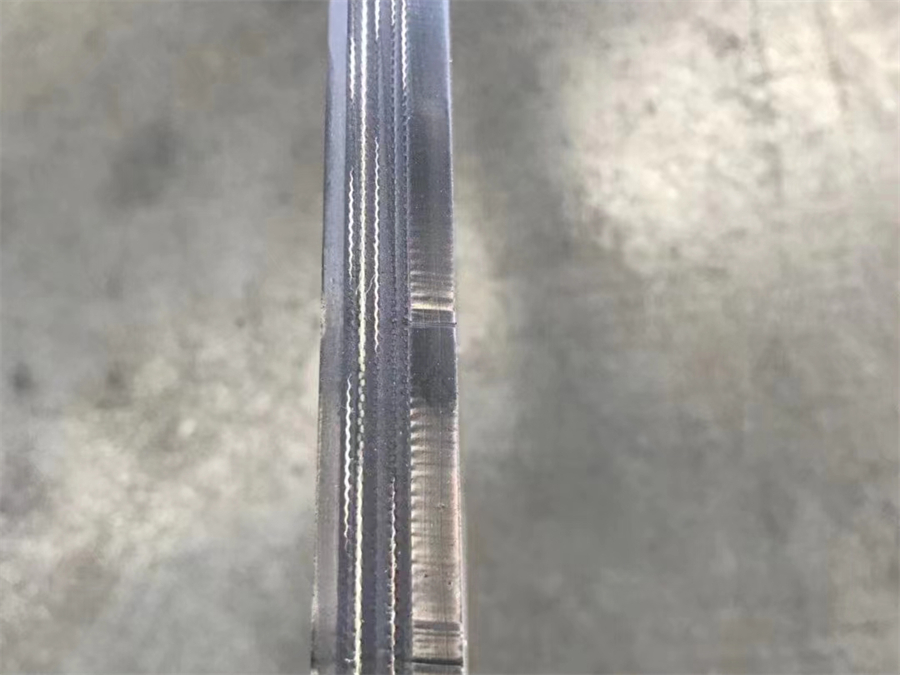

Nylon conveyor belt has high tensile strength and wear resistance. This extends service life and reduces the number of replacements, reducing downtime and maintenance costs. A more durable conveyor belt ensures continuous operation and fewer production interruptions.

Nylon is lighter than many other materials, which can reduce the energy required to operate the conveyor system. Improve the overall efficiency of transporting materials by reducing power consumption.

Nylon conveyor belts perform well in environments with high humidity or extreme temperatures. Resistant to moisture, chemicals, and abrasion, they continue to operate smoothly under harsh conditions, reducing the likelihood of system failure.

The low friction properties of nylon make the belt move more smoothly, reducing wear on the belt and machinery. This reduces maintenance and improves material handling efficiency.

In summary, Nylon conveyor belts can significantly improve the efficiency of industrial processes by increasing durability, flexibility, energy efficiency and reducing maintenance requirements.